|

Corrugated box industry in deep crisis: manufacturers

Tribune News serviceBhanu P Lohumi Shimla, April 1 Himachal Pradesh Corrugated Box Manufacturers Association (HPCBMA) has sought a check on the “monopoly” of paper mill owners, who were announcing frequent increases in prices. This was pushing corrugated box industry into deep crisis . “The corrugated industry is incurring huge losses due to unilateral increase in price and in case the Central government did not intervene, the industry would die its own death in coming years”, Gagan Kapoor, president of Himachal Pradesh Corrugated Box Manufacturers Association (HPCBMA), told The Tribune yesterday. The association has also sought the intervention of the Prime Minister in this regard. Kapoor alleged that the paper mills had increased rates of paper thrice this year. As a result, the 350-odd corrugated box manufacturing units located at Parwanoo, Baddi, Kala Amb, Nalagarh, Solan, Paonta Sahib, Una and Kullu are feeling the pinch as their profits have dwindled to unsustainable level. In order to protest against the arbitrary actions and coercive tactics of paper mill owners, “the joint action committee of corrugated industry of North India has decided not to accept deliveries from paper mills and planned total closure of the corrugated industry for four days in April”, he added. Thousands of Himachalis are employed in corrugated industry and in case the government does not intervene, the survival of the industry would be in peril and employees would lose their jobs, he cautioned. “The rates of the paper have gone up by Rs 4-per kg in the last three months and the corrugated box industry has been directly hit by the hike. In case the Central government did not take urgent steps to check the monopoly of the mill owners, the situation would become precarious” said Kapoor. The HPCBMA president said the Central Government had given special industrial package to Himachal in 2003 which helped corrugated industry and they are using around 50,000 mt of paper every year. However, the repeated increase in the rates of the paper has added to the problem of the industry, he said adding that after the withdrawal of Central industrial package, a large number of pharma units had migrated to other states and the business of local corrugated units had been hit hard. Expressing surprise over the silence of the Central government over the increase in the rates of paper by mills, Kapoor alleged that whenever mills had to increase the rates of paper they reduce the production and create artificial shortage of paper. The Central government had once taken action against cement manufacturers for the same reasons but it is mum on the issue of paper mills, Kapoor added and claimed that due to shrinking profits, some corrugated manufacturers have been forced to shut down. To add to their vows, the transport companies have also increased freight charges, he said and urged the Chief Minister to take notice of the problems being faced by the industry in the state. with thanks http://www.tribuneindia.com/news/himachal/corrugated-box-industry-in-deep-crisis-manufacturers/216474.html

1 Comment

Why should we use Paper Bags? Renewable • Paper Bags are made from paper & corn both can re-grow. • Paper products help to keep land forest intact and reinvested into. • Forestland has steadily increased in western countries to meet the demand of paper. Soon people in India will also start investing in forests. • One acre of trees will every year capture 5,880 pounds of carbon dioxide (major greenhouse gas & cause of global warming). • Trees provide the raw material and more than 65% of the energy needed to create paper. • Using Paper Bags is your commitment to environment that you are contributing to the sustainability, protecting wildlife habitat, and protecting endangered forests. Compostable • Paper Bags do not litter on land and, in a rivers, lakes, and ocean. This packaging material (Paper Bags) will decompose and pose no threat to wildlife and the environment. • Paper Bags are ideal as a container to hold compostable waste. Recyclable • Recycling is most important to achieve sustainable planet. • More than half of all paper in the India is recovered for recycling. In fact Paper used for corrugated boxes or Kraft paper bags is almost 70% recycled and reused. Reusable • Paper Bags are reusable for future visits to stores.. • Paper Bags have many other uses including: - School book covers, gift wrap, and other craft projects - Picnics/Sporting events - Recycling and composting containers - that way the container is recyclable and compostable • When Paper Bags becomes soiled or worn out, it is ready for recycling or composting, continuing the cycle of sustainability · In fact you can earn a return (more than 25%) by selling it scrap dealer. Therefore Kraft Paper Bags and corrugated boxes are one of the most sustainable products in the world.

Brief Facts about Corrugation Industry in India

The Challenges faced by Corrugation SME’s in India

The corrugated packaging industry has been adequately meeting the packaging requirements of the country. It is expected that the government should intervene to resolve their problems otherwise This industry would have a drastic effect on the industry as a whole as packaging material is one of the most significant parts of the supply chain. visit my personal page too http://www.amkur.co.in/my-blog 10 reasons to choose corrugated box for packaging.

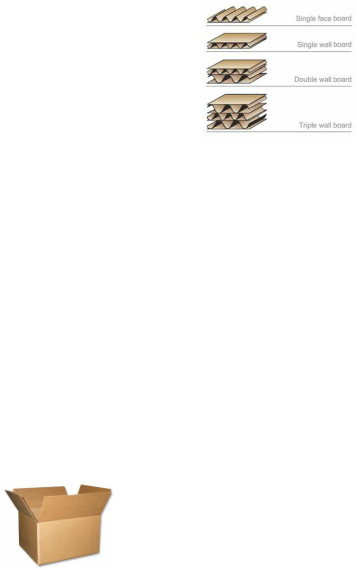

· LOW COST · CAN BE RECYCLED · THE” GREEN TECHNOLOGY STATUS” · NOT HAVE SHARP EDGES · PACK ANYTHING · WE DO NOT WANT TO HURT MOTHER NATURE · DELICATE ELECTRONIC GADGETS CAN BE PLACED · AVAILABLE THROUGHOUT THE YEAR · EASY TO PRINT · MUCH DURABLE Corrugated boxes are used everywhere around us. We can find them in the packaging cover of our refrigerator to our smart-phones. There are many advantages offered by corrugated box which makes them the most popular for packaging purposes. Let us now take a look of some of the reasons that make us chose them.1. The first point is obviously their low cost. They are much cheap when compared to other packaging stuff. Corrugated boxes are manufactured from old cardboard boxes and hence they are cheap.2. Corrugated boxes can be recycled with ease. They are known to be a unique variety of paper so it will degrade easily and on the other hand they can be used to make further boxes.3. For making 30kg of wooden box we have to cut a full grown pine tree. That is, you have to sustain your environment by reusing the resources provided to you as much as possible. We do not want to hurt Mother Nature as she gives us everything, from food to shelter.4. The pressure handling capacity of the boxes is another important reason of its vast popularity. You can pack anythingwith the help of a corrugated box. Even the most popular phone iPhone 4s comes in a corrugated box, so now I guess you got an idea about how reliable it is.5. These boxes will not have sharp edges that might harm us so this can also be counted as an additional advantage of these boxes. The pressure handing capacity of these boxes enables us to stack them against one another and can stop worrying about damaging them.6. If your company is using these boxes you company can easily get the” green technology status” as these corrugated box are made up on paper and doesn’t cause any damage to the environment. No harmful chemicals are used in the manufacture of these boxes.7. There boxes are similar to the ordinary plastic boxes but they are superior because of their durability. They are much durable and will stay for years.8. It is much easy to print the company’s logo and other details in the corrugated box. So in this case also your company can save money.9. The availability of corrugated box is another major advantage. They are available throughout the year. There are many manufacturers of corrugated boxes so we will have a lot of options to buy one whenever we need.10. The corrugated boxes have 3 layers of cardboard and hence even delicate electronic gadgets can be placed inside them.I guess after seeing all these advantages you will ultimately choose corrugated boxes to pack the goods of your company. There are many companies manufacturing corrugated boxes. All you have to do is to do a small research about manufactures of corrugated box and give your order to the best one. Most companies have customer relation officers who will be glad to help you in selecting the right box for your commodity, along with effective price reduction.By Amkur Singh,Amkur Creations Pvt Ltd Paper-to-Corrugated Time Line The first layered form of writing paper was in 950 BC when the Egyptians glued together plant stem layers to use for writing. The first authentic paper was made of bamboo and mulberry fibers. The process was developed by the Chinese in 100 BC. People in Spain, Germany, Italy and France began the first paper mills during the 15th century. The first paper mill in the United States was built in 1690 near Philadelphia. The first production of paper from wood pulp, in 1854, was in England, where production of corrugated paper followed in 1856. Corrugated cardboard, or heavy paper, was used for the first time in 1871 to wrap the flutes of lanterns for shipment. Evolution of Corrugated Packaging The Industrial Revolution caused an expansion of the variety of sizes of corrugated boxes. Today, they may be made to specific dimensions of each article at a reasonable price and are the preferred packaging for shipping.corrugated Corrugated Paper Corrugated paper has been used in some fashion since 1856. The simple unlined corrugated paper was first used inside of a hat for a sweat band lining. A liner was placed on the corrugated paper to keep the flutes from stretching in 1874. This is the type of corrugation used in corrugated boxes familiar to most people. Emergence of the Corrugated Box A process was developed in 1894 to cut, fold and assemble a corrugated box. Mass production of the box began during the same year. The same year, Wells Fargo became the first company to use corrugated cardboard boxes for small shipments of freight. The corrugated box gained governmental approval in 1903 to be used was a shipping container. It was at this time that cereal companies began using this method for shipping their cereal. Corrugated Market Sky-rocketed Corrugated production gained significant speed during 1910. There were approximately 50 companies making corrugated boxes by this time due to the fact that it was an affordable, lighter weight, readily available product that companies could use for shipping. Design Corrugated boxes were designed in a range of sizes to accommodate the needs of their customers. They adapted well to volume packing, were of uniform quality, easy to seal and easy for workers and customers to handle. The corrugated box offered cushioning for the items it contained. The box also allowed for manufacturers to print on the outside in an inexpensive way to advertise.  What is Corrugated box (Corrugated) marked with parallel folds, ridges or furrows bent into regular curved folds or grooves. Process of making such regular curved folds is called corrugation. Corrugated box is box made out of corrugated box made of paper based corrugated fiberboard Corrugated fiberboard Corrugated fiberboard is a paper-based material consisting of a fluted corrugated sheet and one or two flat linerboards. It is widely used in the manufacture of corrugated boxes and shipping containers. Corrugated Box |

AuthorI am aspiring entrepreneur having good experience in paper packaging industry. Archives

April 2016

Categories |

RSS Feed

RSS Feed